You shouldn’t follow a rigid schedule; instead, monitor your pressure gauge as your primary indicator. Clean your filter when pressure rises 8-10 psi above baseline, typically every 4-6 weeks during peak season. Cartridge filters need cleaning more frequently than sand or DE filters. Environmental factors like heavy debris and algae blooms increase cleaning demands. Recording weekly pressure readings helps you identify trends and optimize your maintenance routine for peak performance and extended filter lifespan.

Understanding Your Filter Type and Its Cleaning Schedule

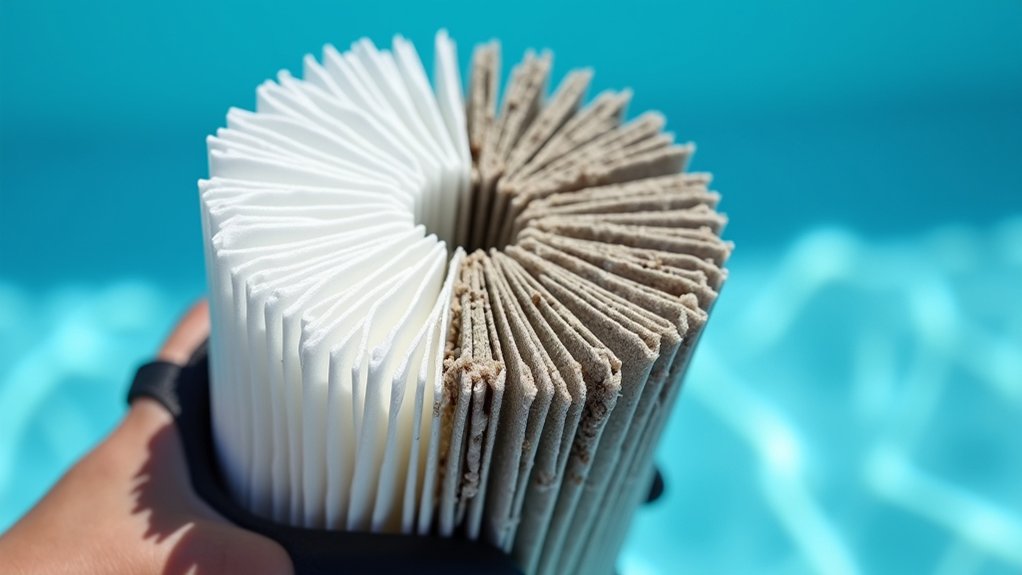

Before you can effectively clean your pool filter, you’ll need to identify which type you’re operating: cartridge, sand, or diatomaceous earth (DE), since each demands different maintenance protocols and cleaning intervals. Cartridge filters require cleaning every 4–6 weeks during peak season, while sand and DE filters typically need backwashing at similar intervals. Your filter pressure gauge serves as your primary indicator; clean when pressure rises 8–10 psi above baseline. Understanding your specific filter type directly determines ideal filter lifespan and maintenance success. Cartridges last 2–3 years, sand filters 3–5 years, and DE filters need deep cleaning every 6–12 months. Implementing proactive winterization steps, thorough cleaning and drying for cartridges, complete backwashing for sand and DE, prevents freeze damage and extends equipment life considerably. Regular monitoring of environmental factors such as heavy rainfall, seasonal debris accumulation, and bather load will help you adjust your cleaning schedule accordingly to maintain optimal filter performance year-round. Each filter type captures different particle sizes, affecting how frequently debris accumulates and necessitates cleaning.

Recognizing When Your Filter Needs Immediate Cleaning

You’ll recognize pressure gauge warnings when your readings climb 8–10 psi above normal, signaling immediate filter cleaning is required. Water clarity decline, persistent cloudiness even after chemical balancing or visible debris accumulation, indicates your filter can’t effectively remove contaminants and needs urgent attention. Both warning signs demand prompt intervention to prevent algae growth, reduced flow, and potential equipment damage. High pressure can put strain on the pump, increasing the risk of costly repairs that extend beyond simple filter maintenance. Frequent backwashing requirements also suggest reduced filter efficiency and may indicate your filter is nearing the end of its typical 5 to 10 year lifespan. Neglecting these warning signs can result in poor water quality that compromises both your swimming experience and the longevity of your pool system.

Pressure Gauge Warning Signs

Your pool filter’s pressure gauge is the most reliable indicator of system health, and learning to read it correctly can prevent costly equipment damage. Monitor these critical warning signs:

- Sudden pressure spikes that jump 8–10 PSI above baseline often signal filter clogs or air entrapment, requiring immediate pump shutdown to prevent rupture.

- Gauge malfunctions like stuck needles or failure to return to zero when the pump’s off indicate mechanical failure and compromise your ability to detect flow issues. A bent or warped dial on the gauge may cause the needle to remain in place even after the pump is shut off. Regularly venting the filter using the air relief valve helps eliminate trapped air that can artificially elevate pressure readings.

- Persistent elevation above 30 PSI demands prompt intervention, as continued operation risks tank rupture and equipment failure.

Check your gauge weekly. If pressure readings remain unreliable after cleaning, replace the gauge with a 0–60 PSI-rated unit. Don’t ignore abnormal readings; they’re your system’s early warning system.

Water Clarity Decline Indicators

While a pressure gauge warns of mechanical stress, water clarity reveals the filter’s actual performance in removing contaminants. You’ll notice immediate water appearance indicators when your filter requires cleaning: cloudiness obscures pool features, dull coloration replaces the characteristic blue, and loss of sparkle signals inadequate filtration.

Odor and sensory pollution provide additional warning signs. Persistent chlorine smells indicate ineffective oxidation, while unpleasant odors suggest organic buildup. Swimmers may experience eye and skin irritation from elevated, heightened turbidity and chemical imbalances. Non-living organics, oils, and tannins that bypass a clogged filter contribute to chlorine demand and accelerate water clarity decline. Following the PWTAG Code of Practice ensures that filter maintenance aligns with industry technical operation standards and maintains proper water chemistry balance.

Visible algae blooms, particularly in corners, emerge when filtration declines. Slippery surfaces indicate biofilm accumulation. Fine suspended debris that your filter can’t remove reduces clarity substantially. A consistent cleaning schedule prevents this buildup of contaminants and maintains safe swimming conditions.

These indicators collectively demonstrate your filter’s compromised performance and necessitate immediate cleaning to restore water quality and maintain safe swimming conditions.

Pressure Gauge Monitoring: Your Key Performance Indicator

Because your pool’s filtration system can’t communicate its needs verbally, the pressure gauge becomes its voice, and you’d be wise to listen closely. You’ll establish a baseline reading after each filter cleaning to create your system’s performance standard. Monitor these critical indicators:

- Pressure measurement stability – Record weekly readings at consistent times to identify trends and spot anomalies before they worsen

- Gauge placement – Position your gauge at eye level for precise readings and clear visibility during routine checks

- Sudden fluctuations – Pressure spikes 10+ psi above baseline signal filter clogging; sharp drops indicate suction-side blockages or pump issues

You’ll recognize system problems early by tracking pressure patterns. Replace gauges showing erratic readings, physical damage, or persistent zero readings. This vigilant monitoring protects your pump motors and maintains effective circulation efficiency. A typical pressure gauge is round with an indicator needle and displays a range from 0 to 4 bar, making it easy to spot when readings deviate from your established baseline. The sensitive diaphragm inside expands or contracts based on pressure changes, translating internal system conditions into measurable values on the gauge scale. Normal pressure typically falls between 10 psi to 25 psi depending on your filter size, pump strength, and filter cleanliness.

Seasonal and Environmental Factors That Increase Cleaning Frequency

You’ll notice your filter’s cleaning frequency shifts dramatically with summer peak usage, as increased swimmer load and sunscreen introduce organic contaminants that accelerate clogging. Environmental debris accumulation, leaves, pollen, and dust from nearby vegetation and weather events compounds this burden, particularly after storms or during windy seasons. Weather-related filter stress, including heavy rainfall and temperature fluctuations, can overwhelm your filtration system and demand immediate post-event cleaning to maintain water clarity and chemical balance. Setting reminders for monthly checks helps you stay on top of these seasonal changes and prevents filter performance from deteriorating during high-demand periods.

Summer Peak Usage Demands

Summer transforms pool maintenance into a high-demand operation. You’ll face accelerated filter clogging from increased bather loads and extended operating hours. Heavy usage introduces lotions, oils, and debris that rapidly overwhelm your filtration system.

Key demands during peak season include:

- Microorganism growth surges – Heightened temperatures create ideal breeding conditions for bacteria and algae, requiring weekly filter cleanings in frequently used pools

- Chemical imbalance impacts – Heat accelerates sanitizer breakdown while increased dosing promotes precipitate formation that fouls filter media

- Organic contaminant accumulation – Children’s activities and pool parties introduce substantial organic matter, demanding immediate post-event backwashing

You’ll need to monitor filter pressure readings closely and respond to algae outbreaks immediately. After high-usage events, restore optimal flow by cleaning or backwashing without delay to prevent recontamination and maintain water clarity.

Environmental Debris Accumulation

While peak-season bather loads stress your filtration system, environmental debris compounds filter strain throughout the year. Seasonal foliage shedding, particularly during autumn and spring, overwhelms filters with leaves, pollen, and organic matter that accelerate clogging and reduce water flow effectiveness. Airborne pollutant accumulation from dust storms, construction activity, and wind events introduces fine particulates that rapidly load your filter media.

Your proximity to trees, vegetation, and landscaping directly impacts cleaning frequency. Overhanging branches deposit seed pods, blossoms, and twigs that intensify seasonal spikes. Wildlife and pet activity introduce feathers, hair, oils, and droppings that increase microbial content.

To combat these environmental pressures, monitor your filter pressure gauges closely during changing seasons. Implement immediate debris removal and consider installing wind breaks or pool covers. Strategic vegetation management around your pool considerably reduces filter cleaning intervals and maintains ideal system performance.

Weather-Related Filter Stress

Because weather patterns directly accelerate filter contamination and reduce system efficiency, understanding seasonal stressors is critical to maintaining consistent water clarity and filtration performance.

You’ll encounter distinct challenges across seasons:

- Heat waves: Heightened temperatures double chlorine demand and accelerate UV breakdown, while rapid microorganism growth stresses your filter media. Increase cartridge rinsing to every two weeks during peak heat.

- Heavy rainfall: Storms cause chemical disruption during storms by diluting sanitizers and introducing bacteria and algae spores. Backwash immediately after significant precipitation to prevent system overload.

- Cold snaps: Freezing temperatures damage housings and connections. Thoroughly drain and dry filter media before winter storage to prevent mold and degradation.

You’ll also face increased organic loads during summer peaks and seasonal pollen influxes. Monitor filter pressure regularly; these conditions demand more frequent maintenance than standard intervals suggest.

The Risks of Neglecting Regular Filter Maintenance

When you postpone filter cleaning and maintenance, you’re not just compromising water clarity; you’re inviting a cascade of problems that threaten swimmer safety, damage your equipment, degrade water quality, and drain your wallet. Neglected filters accumulate debris that fosters algae and bacteria growth, exposing swimmers to pathogens and chemical imbalances. Clogged filters force your pump to operate under excessive pressure, accelerating wear and triggering costly breakdowns. Poor filtration creates health code violations and regulatory compliance concerns, potentially subjecting you to fines or closure orders. Additionally, you’ll face escalating chemical demands, frequent equipment replacements, and heightened energy consumption. The financial burden compounds quickly, professional cleaning, resurfacing from algae staining, and premature cartridge replacements drain resources far exceeding routine maintenance costs. Regular filter cleaning prevents these cascading failures entirely.

Best Practices for Applying Filter Cleaner Products

The foundation of effective filter cleaning rests on choosing the right product for your specific filter type and following manufacturer guidelines precisely. You’ll maximize results by optimizing chemical dosing according to label instructions and maintaining proper soak duration, typically several hours or overnight for heavy buildup.

Effective filter cleaning requires selecting the right product for your filter type and following manufacturer guidelines with precise chemical dosing and proper soak duration.

- Pre-inspect your filter for physical damage before cleaning to prevent ineffective treatment and equipment strain

- Submerge cartridges and D.E. grids completely in diluted cleaner, rotating elements periodically for even distribution

- Rinse thoroughly post-soak to eliminate residual chemicals before reassembly

You must avoid exceeding recommended soak times, as prolonged exposure degrades filter media. Always depressurize your system and wear protective gloves and eyewear during application. Dispose of cleaning solutions responsibly, preventing environmental contamination while protecting your pool’s water chemistry balance.

Balancing Cleaning Needs With Filter Longevity

While proper cleaning technique prevents equipment damage and maintains water clarity, you’ll also need to balance how often you clean against the filter’s finite lifespan. Excessive cleaning accelerates fiber deterioration, reducing your cartridge’s effectiveness prematurely. You’re aiming for filter composition optimization by monitoring pressure gauges rather than following rigid schedules. When pressure rises 8-10 psi above baseline, that’s your signal to clean.

Post-cleaning restoration techniques matter too. After each cleaning cycle, allow your filter to dry completely before reinstalling to prevent fiber damage. Track cleaning frequency, Unicel recommends replacing cartridges after 12-15 cleanings. If you’re cleaning more frequently than every two weeks during peak season, you’re likely shortening your cartridge’s 3-5 year lifespan unnecessarily. Strategic maintenance preserves both water quality and equipment longevity.

Creating a Maintenance Log to Optimize Your Cleaning Routine

By documenting each cleaning event systematically, you’ll establish the data foundation needed to optimize your filter maintenance routine and validate regulatory compliance.

Systematic documentation of cleaning events creates the data foundation for optimizing filter maintenance and ensuring regulatory compliance.

Your maintenance log captures critical information that drives operational decisions. You’ll record:

- Cleaning specifics, date, time, method (backwashing or chemical), and operator initials for accountability

- Performance metrics, filter pressure readings, flow rates, and water quality results before and after cleaning

- Anomalies, pressure spikes or flow drops indicating unscheduled maintenance needs

Schedule adherence becomes measurable when you track actual cleaning intervals against manufacturer recommendations. This trending analysis reveals whether your routine aligns with bather load and environmental conditions. Log preservation for at least two years satisfies regulatory requirements and supports permit renewals. Digital cloud-based storage guarantees accessibility while maintaining backup capability, enabling you to audit logs efficiently during inspections and refine your cleaning protocol.

Frequently Asked Questions

Can I Use the Same Filter Cleaner Product for Cartridge, Sand, and DE Filters?

No, you shouldn’t use the same cleaner across filter types. Each filter type, cartridge, sand, and DE requires different filter type compatibility approaches. Cartridge filters need mild agents that won’t damage pleated fabric, while sand filters require products that dissolve mineral deposits. DE filters demand specialized formulas protecting grids. Using the wrong cleaner voids warranties and damages media. Your cleaning frequency considerations must align with each filter’s specific requirements. Always verify product compatibility before purchasing to guarantee ideal performance and durability.

What’s the Difference Between Backwashing and Chemical Soaking for Filter Maintenance?

You’ll use backwashing for quick debris removal; it reverses water flow through your filter in 3–5 minutes and doesn’t require chemicals. However, chemical soaking tackles deeper contaminants like oils and scale that backwashing can’t remove. While backwashing maintains efficient filter operation weekly, you’ll need chemical soaking annually for thorough restoration. Your proper filter maintenance schedule combines both: backwashing regularly for routine upkeep and soaking periodically for extensive cleaning.

How Do I Know if My Filter Is Undersized for My Pool?

You’ll determine if your filter’s undersized by checking whether you’re achieving proper turnover rates. Evaluate your pool size requirements against your filter’s GPM rating, residential pools need complete circulation every 8 hours. You should monitor pressure gauge readings; consistently high pressures indicate overload. Watch for cloudy water, frequent backwashing cycles, and debris returning to your pool. If you’re replacing filter media excessively or experiencing algae despite chemical treatment, you’ve likely undersized your filtration system. Calculate your filter flow capacity to confirm adequate sizing.

Will Filter Cleaner Damage My Filter if I Use It Too Frequently?

You won’t damage your filter with chemical cleaners when you follow label directions. However, excessive usage of harsh mechanical methods, like power washing, will degrade your cartridge pleats and shorten filter lifespan dramatically. Stick to gentle hosing and annual chemical soaks instead. Over-cleaning wastes resources without providing benefits. Your filter’s condition and pressure readings should guide your cleaning schedule, not arbitrary frequency assumptions.

What Should I Do if Pressure Remains High After Cleaning the Filter?

If you’ve cleaned your filter and pressure remains heightened, you’ll need to troubleshoot systematically. First, check your filter pressure gauge for accuracy; faulty gauges often give misleading readings. Next, inspect filter components for damage, debris, or improper reassembly. Examine return valves for blockages and verify the cartridge isn’t collapsed. If these steps don’t resolve the issue, consider replacing worn media or calling a professional to assess potential internal equipment malfunctions.