Your pool filter housing is the structural barrier that contains hazardous contaminants and withstands constant pressure cycles from your pump. If you’ve got an undersized or low-rated housing, you’re risking ruptures, leaks, and catastrophic system failure. Quality materials like stainless steel resist corrosive chemicals, while proper gasket seating and fastener integrity prevent dangerous spills during maintenance. A well-maintained housing protects your water quality, your safety, and your equipment investment, but there’s much more to understand about getting this right.

Durability and Structural Integrity of Filter Housings

How long will your pool filter housing actually last? Your answer depends on material selection and maintenance practices. Steel housings deliver 30-year longevity with proper care, while stainless steel (316 grade) excels in corrosion resistance against chlorine and sanitizing chemicals. GRP and polypropylene housings typically span 10–40 years, though sunlight exposure degrades plastic over time. Quality construction matters; high-strength materials withstand pressure cycles better than inferior alternatives. You’ll maximize leak prevention and structural integrity by replacing wear parts annually and addressing cracks immediately. Environmental factors like humidity and UV exposure accelerate degradation. For steel filters specifically, maintaining the internal epoxy lining is crucial for longevity, as carbon steel requires protection against chlorinated pool water through a two-part epoxy lining process with minimum 500-micron thickness. Regional climate conditions such as Florida’s warm and humid environment can significantly impact filter housing durability and require enhanced maintenance schedules. Regularly inspecting your housing for signs of damage allows for timely maintenance before structural issues compromise your filtration system. Your housing’s durability hinges on material quality, consistent maintenance, and adherence to pressure specifications. Invest in quality construction; it protects your entire filtration system.

Contaminant Containment and Operator Safety

When you maintain your pool filter, the housing acts as a critical barrier that contains hazardous contaminants and residual chemicals until you’ve safely depressurized the system. You’ll benefit from proper filter media handling procedures that minimize your direct contact with trapped bacteria, algae, and chemical residues during replacement or cleaning operations. Secure latching mechanisms and optimized housing designs guarantee you can perform routine maintenance without exposing yourself or your surroundings to dangerous particulates or chemical splashes. Proper pool maintenance also extends the lifespan of your filter equipment by protecting internal components from premature wear and corrosion caused by uncontained debris and chemical exposure. Regular filter cleaning and maintenance help you maintain proper chemical balance and ensure your circulation system operates efficiently to support overall water quality management. Backwashing sand filters when pressure rises 8-10 psi above normal prevents excessive buildup of trapped contaminants that can compromise housing structural integrity and reduce filtration effectiveness.

Barrier Protection During Maintenance

Because filter housings serve as the primary containment system during maintenance operations, their integrity directly affects both environmental safety and operator protection. You’ll maintain effective barriers by prioritizing proper gasket placement and secure fastener upkeep during reassembly.

| Maintenance Task | Primary Benefit | Risk if Neglected |

|---|---|---|

| Pressure release before opening | Prevents sudden discharge injuries | Pressurized water ejection |

| Gasket inspection and seating | Eliminates leaks and spills | Chemical contamination spread |

| Fastener tightening verification | Guarantees housing closure integrity | System debris infiltration |

| Housing crack assessment | Safeguards pump components | Circulation system damage |

You’ll minimize contaminant escape and chemical spills by preserving all connections remain dry and secure. Releasing system pressure beforehand prevents dangerous fluid release. Routine housing inspections identify compromised seals before they cause environmental or safety incidents. Leaks and cracks in the filter housing can be repaired with epoxy or by replacing damaged parts to maintain system integrity. Implementing early warning signs detection during your maintenance checks helps catch potential housing failures before they compromise your filtration system’s protective capabilities. Your attention to these containment protocols protects both personnel and equipment throughout filter servicing operations. Since plastic housings can warp and weaken due to prolonged sunlight exposure, storing your filter in shaded areas extends its protective lifespan and maintains structural integrity during maintenance procedures.

Safe Filter Media Handling

While filter housing integrity protects against system leaks, you’ll also need to control hazards from the filter media itself during handling and replacement. Crystalline silica dust from pool filter sand causes respiratory irritation and can lead to silicosis with prolonged exposure. Your media containment strategies should include keeping filter media moist during removal to prevent fine particles from becoming airborne. Use sealed containers and soft brushes for mechanical removal, avoiding dry sweeping or air-based cleaning methods. Dust exposure mitigation requires wearing N-95 respiratory protection, safety goggles with side shields, and sturdy work gloves. Always power down pool systems and release pressure before opening filter housings. Isolate maintenance areas from public access to minimize bystander contamination exposure. Before addressing any filter leaks or malfunctions, immediately shutdown the pump to prevent further contamination exposure during maintenance work. A water testing kit] should be used to monitor water chemistry before and after filter maintenance to ensure safe operating conditions. Regular filter cartridge replacement every 1 to 2 years ensures that degraded filter media does not become an additional dust hazard during maintenance procedures.

System Compatibility and Pressure Management

To protect your pool system from equipment failure and safety hazards, you’ll need to ascertain your filter housing matches both your pump’s capabilities and your pool’s operational demands. Your housing must withstand the maximum operating pressure your pump generates; undersized or low-rated housings risk ruptures and leaks. Flow rate coordination is critical: your filter’s maximum GPM rating must meet or exceed your pump’s output to prevent excessive internal pressure. If you’re handling saltwater systems, you’ll need corrosion-resistant housings specifically rated for chlorination equipment compatibility. Regular pressure gauge monitoring detects clogs early, preventing chronic overpressure and premature failure. Purchasing a slightly larger filter housing can provide greater safety margins and more efficient filtration performance than the minimum required size. Different filter types, such as sand, cartridge, and DE filters, offer varying levels of particle removal and maintenance requirements. Proper filter maintenance is essential for ensuring your housing components function efficiently and extend the operational lifespan of your equipment. Mismatched components compromise filtration efficacy and void warranties. Always verify manufacturer specifications to affirm your housing’s pressure rating, flow capacity, and material composition align with your pool’s unique requirements.

Maintenance and Accessibility for Optimal Service

Three critical factors define whether your pool filter housing serves you reliably over time: how easily you can access its components, how frequently you’ll need to perform maintenance, and whether the design actively supports safe, efficient service.

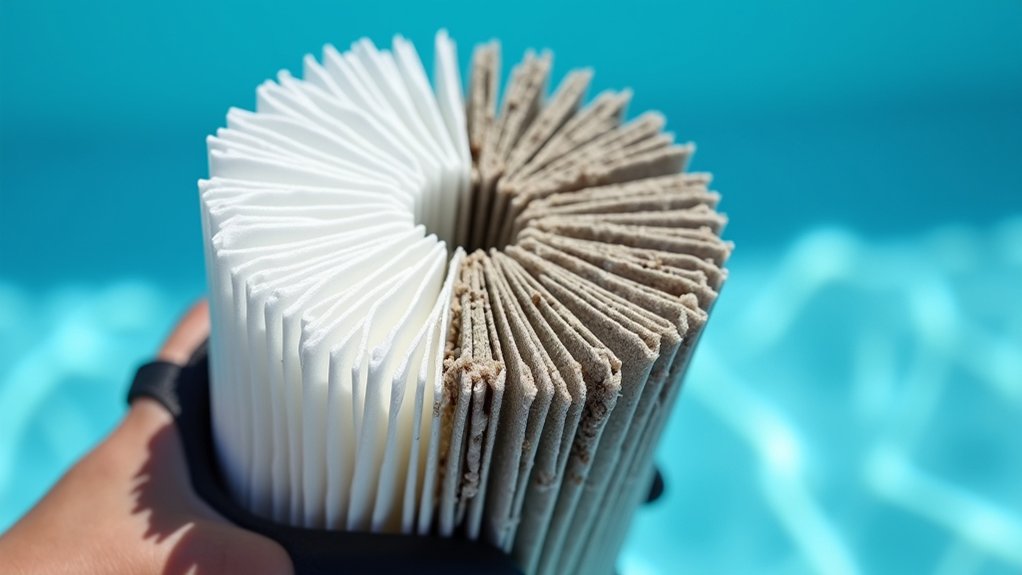

User-friendly operations begin with transparent housings and quick-access clamps, enabling you to inspect debris without disassembly. Simplified maintenance procedures depend on removable components and accessible locations that eliminate specialized tools. You’ll perform cartridge cleanings every 2–6 weeks during peak use; ergonomic designs reduce time and physical exertion. Regular filter cleaning prevents the accumulation of contaminants that can compromise water quality and compromise your pool’s overall health.

Well-designed housings incorporate handle grips, non-slip surfaces, and protective shielding that enhance safety during service. Durable materials resist cracking, while tight-sealing gaskets prevent leaks. Accessible housings facilitate preventive maintenance, minimizing pump strain and reducing long-term repair costs substantially.

Regulatory Compliance and Water Quality Standards

You’ll need to guarantee your pool filter housing meets established safety standards to prevent cross-contamination and maintain compliant water quality. Your system must support proper filtration and disinfection, key requirements that regulatory agencies like the CDC enforce through daily monitoring of disinfectant residuals, pH levels, and microbial counts. By selecting housing that accommodates robust filtration and protects against system failures, you’re directly safeguarding against pathogen exposure and maintaining the chemical balances that keep recreational water safe.

Meeting Safety Standards

Because pool filter housings directly impact water quality and public health, they’re subject to rigorous regulatory requirements that you’ll need to understand and implement. Your housing must comply with NSF/ANSI 50-2024 standards, which establish component strength requirements and material composition factors essential for safe operation. You’re responsible for ensuring materials are non-toxic, impervious, and capable of withstanding operational pressures without deforming. The housing design you select must support backflow prevention and maintain structural integrity during routine maintenance access. You’ll need written compliance documentation from licensed contractors verifying installation meets local health department codes. Regular inspections confirm your system meets turbidity and contaminant standards. By adhering to these safety standards, you protect both water quality and public health effectively.

Preventing Cross-Contamination Issues

While meeting safety standards establishes the baseline for structural integrity, preventing cross-contamination requires you to examine how housing design, sanitation, materials, and maintenance protocols work together to maintain water quality between filtration cycles.

Your filter housing must support effective decontamination practices that regulatory authorities demand. Consider these critical factors:

- Electropolished interiors eliminate microscopic crevices where contaminants accumulate and biofilms form

- Removable diaphragm plates and sloped bases enable complete drainage, preventing carryover between cycles

- PTFE or fluoropolymer coatings resist aggressive disinfectants without leaching corrosion byproducts

- Rapid disassembly design reduces system downtime and contamination exposure during maintenance

- Exhaustive documentation demonstrates compliance with CDC and local public health codes

Don’t confuse housing aesthetics with hygiene; mechanically polished surfaces harbor bio-contaminants despite their appeal. Your material selection and design sanitation directly determine whether your filtration system protects water quality or compromises it.

Equipment Longevity and Long-Term Cost Efficiency

A well-maintained filter housing directly determines how long your entire pool system will operate cost-effectively. Your housing integrity protects pumps, heaters, and chlorine generators from debris circulation, extending their functional lifespans to 8–12 years. Without proper housing protection, you’ll face accelerated equipment failure, scaling, and corrosion, triggering premature replacements that inflate capital expenses.

Investing in robust filter housing delivers reduced operating costs by minimizing unscheduled maintenance calls and emergency repairs. You’ll avoid the compounding expense of replacing multiple system components simultaneously. A secure housing maintains consistent hydraulic pressure, preventing stress-induced failures across your filtration network. Over five to ten years, preventive housing maintenance generates substantial savings while ensuring reliable system performance and enhanced visual appeal of properly functioning equipment.

Frequently Asked Questions

What Materials Are Best for Filter Housings in Different Climate Conditions?

You’ll want to match your housing material to your climate’s demands. For harsh environments, you’re choosing stainless steel for superior corrosion resistance and temperature resilience. In coastal areas, you’re selecting fiberglass-reinforced plastic to combat salt air. You’re picking polypropylene for mild, temperate regions where cost-effectiveness matters. For controlled indoor pools, you’re using PVC for chemical resistance. Each material’s properties directly address your specific environmental stressors, ensuring ideal filtration system longevity.

How Often Should I Inspect My Filter Housing for Signs of Wear?

You should inspect your filter housing every 1–3 months during active pool season as part of routine maintenance checks. Conduct visual inspections with each filter cleaning or backwash cycle every 4–6 weeks. Track pressure gauge readings to identify performance declines. Implement pre-season checks and post-storm inspections for damage. You’ll want annual replacement considerations if you discover significant cracks, warping, leaks, or corrosion. High-use pools may justify monthly inspections.

Can I Upgrade My Existing Filter Housing to a Newer Model?

Yes, you can upgrade your existing filter housing to a newer model. You’ll need to verify that your custom housing dimensions match your plumbing’s pipe diameter and connection type. Check pressure ratings and flow rates against manufacturer specs. Modern housings often feature improved filter housing accessibility for easier maintenance. Consider whether you’ll need adaptors or re-plumbing. Professional assessment helps prevent compatibility issues and guarantees ideal filtration system performance post-installation.

What Is the Typical Lifespan of a Quality Pool Filter Housing?

You’ll typically get 10–20 years from a quality pool filter housing, depending on material and conditions. With proper filter housing installation and routine filter housing maintenance, you can maximize that lifespan greatly. Premium materials like fiberglass or metal outlast standard plastic versions. Sun exposure and chemical balance are critical factors; unprotected housings degrade faster. Regular inspections and immediate repairs to cracks or warping help guarantee your housing reaches its full potential.

How Do I Know if My Filter Housing Needs Replacement Versus Repair?

You’ll need replacement if you’re dealing with cracks, persistent leaks, or tank bulging, issues that repair can’t fix safely. However, you can repair minor O-ring leaks or clamp issues. Consider replacement when you’ve made multiple repairs recently, experience constant high pressure despite cleaning, or notice structural damage. Proper installation techniques and appropriate filter selection during replacement prevent premature failure, ensuring your system’s longevity and reliable performance.