You’ll maintain ideal pool water quality by understanding how each filter component functions together. Sand filters trap debris through graded media layers, while cartridge filters achieve fine 5 20 micron capture. DE filters provide superior 1 5 micron filtration using diatomaceous earth powder. Your pressure gauge monitors system performance, and O-rings, gaskets, and seals prevent costly leaks. Filter housing, clamps, and drain plugs complete the sealed system. Each part plays a critical role in keeping your pool crystal-clear and safe.

Sand Filters: Trapping Particles Through Graded Media

Because sand filters rely on layered media to capture debris, understanding their construction is essential to guaranteeing your pool’s filtration system performs at its best. You’ll find most sand filters use fiberglass, concrete, or metal housings containing special-grade silica sand with grain sizes of 0.4 0.8 mm. This irregular, squarish shape creates ideal conditions for trapping particles down to 20 40 microns as water flows downward through the bed.

For enhanced performance, you can implement multilayer configurations combining anthracite, silica sand, and coarse gravel. These arrangements improve particle capture and dirt distribution. Media size directly affects your flow rate optimization, properly sized sand ensures adequate water circulation while maintaining efficient filtration. Glass media presents an alternative, offering improved dirt distribution and reduced maintenance. When the sand bed becomes saturated with trapped debris, a backwashing process reverses water flow to dislodge and remove accumulated particles. Sand replacement should occur every 3 to 4 years to maintain optimal filtration performance. You’ll achieve the best results by matching media depth and sizing to your pool’s specific requirements.

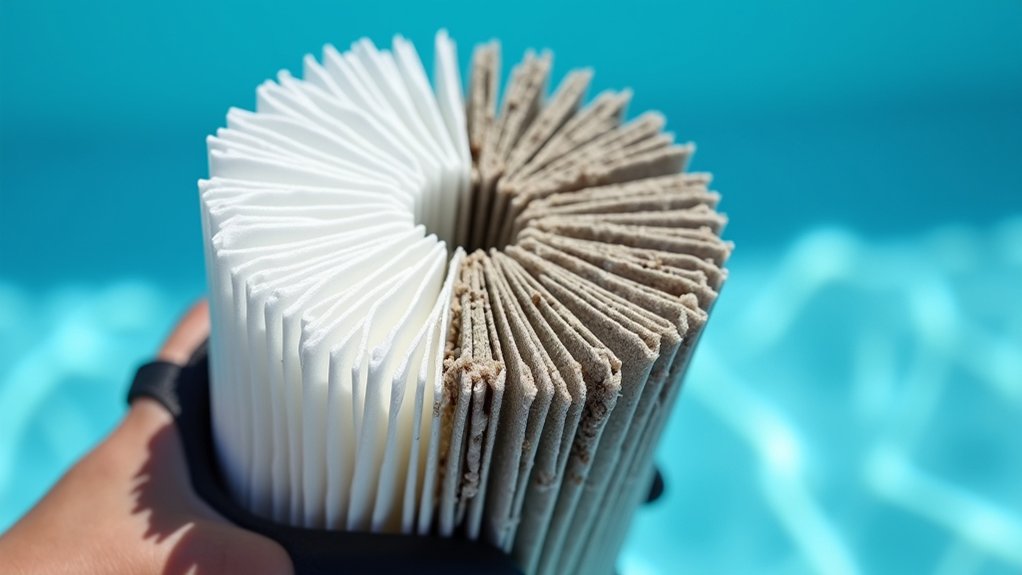

Cartridge Filters: Fine Filtration With Pleated Synthetic Material

While sand filters rely on layered media to trap debris, cartridge filters take a different approach by using pleated synthetic fabric, typically polyester, wrapped around a cylindrical core to achieve finer particle capture. You’ll appreciate how the pleated media design dramatically increases surface area, enhancing dirt holding capacity and extending cleaning intervals. According to the Pool & Hot Tub Alliance, cartridge filters are highly efficient and low-maintenance options for keeping pool water clean and safe. Cartridge filters must be replaced every 1 to 3 years depending on pool debris and usage patterns. To maintain peak performance, cartridges require thorough cleaning 2-3 times annually to prevent debris buildup and extend their operational lifespan.

| Feature | Specification | Benefit |

|---|---|---|

| Micron Rating | 5 20 microns | Captures fine particles |

| Media Type | Pleated polyester | Increased surface area |

| Cleaning Method | Hose off only | No backwashing required |

| Lifespan | 1 3 years | Predictable replacement costs |

| Water Savings | ~200 gal/month | Reduced consumption vs. sand |

Your cartridge requires minimal maintenance; simply remove and rinse every 3 6 months. Installation fits seamlessly into your circulation line, operating quietly while delivering reliable fine filtration without energy-intensive backwashing.

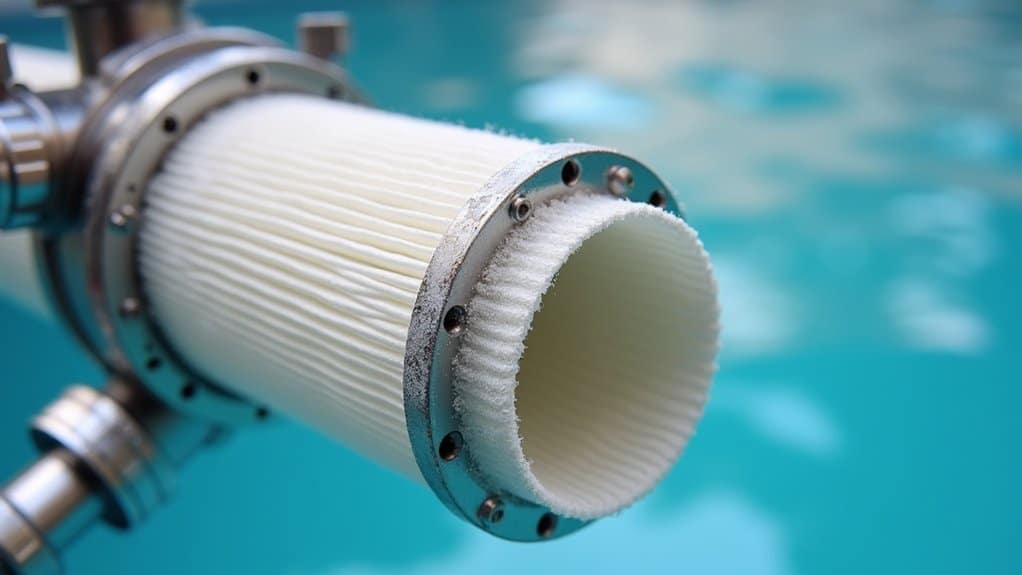

Diatomaceous Earth Filters: Achieving Micron-Level Filtration

You’ll achieve superior micron-level filtration, down to 1 5 microns, by mastering the DE powder application process, which requires pre-coating clean, wet filter grids with a uniform porous layer before each filtration cycle. Your system’s exceptional clarity depends on proper grid maintenance and replacement, as tears or damage cause bypass that compromises water quality and defeats the filtration’s core advantage. After backwashing, you must add fresh DE powder via the skimmer with slurry mixing, and periodically remove grids for thorough cleaning to prevent oil and mineral buildup that reduces effectiveness. When pressure increases 8 to 10 PSI above normal operating levels, it’s time to initiate the backwashing process to restore optimal filter performance. The porous coating on your filter grid continuously traps fine particles while allowing water to pass through during the filtration cycle. This DE coating becomes saturated with trapped particles over time, which is why regular maintenance is essential to sustain the labyrinth of tiny passages that make DE filters so effective at removing even the smallest contaminants.

DE Powder Application Process

How does DE powder actually create filtration? You’ll add DE powder slowly through your pool skimmer while your filtration system runs. The powder mixes with water, traveling through plumbing to coat your filter grids evenly. This coating creates the fine, porous barrier that traps debris down to 3-5 microns, which is far smaller than what the naked eye can detect. The DE powder acts like a sponge, absorbing dirt and debris particles as water passes through the microscopic skeletons of diatoms.

You’ll monitor your pressure gauge throughout the application, and stop when pressure reaches normal operating range (10 13 PSI). Apply slowly to prevent pipe clogging or uneven grid coating. Wear a dust mask for respiratory protection.

Your DE reapplication schedule depends on pressure increases. When pressure spikes 8 10 PSI above baseline, backwash and reapply. Typically, you’ll backwash every four weeks. After standard backwashing, reapply about 80% of your original amount since some DE remains. Following your grid cleaning procedure, use the full recommended dosage.

Superior Micron Filtration Capability

Because DE filters capture particles as small as 2 5 microns, they outperform sand and cartridge filters by a significant margin. You’ll remove bacteria and some viruses that slip through sand filters’ 20 40 micron range and cartridge filters’ 25 100 micron capability.

Your contaminant capture effectiveness extends to invisible particles, trapping Cryptosporidium and suspended solids that naked eyes can’t detect below 35 microns. The fossilized diatom shells create microscopic channels that mechanically and adsorptively remove both organic and inorganic contaminants simultaneously. The diatomaceous earth powder is added directly to the skimmer, where it dissolves in pipes and coats the filter grids before water passes through. Proper respiratory protection is essential when handling diatomaceous earth due to its carcinogenic nature. Proper maintenance of your DE filter system requires monitoring for potential security threats to your pool’s water quality infrastructure.

This superior water clarity improvement results directly from the filter cake formation on DE-coated grids. You’ll achieve crystal-clear water with reduced biological and physical contaminants, decreasing your chlorine consumption and maintenance demands while providing enhanced protection against waterborne pathogens.

Grid Maintenance and Replacement

Three critical maintenance practices, regular cleaning, thorough inspection, and timely replacement, ensure your DE filter grids sustain their superior micron-level filtration capability. You’ll backwash monthly or when pressure rises 8 10 psi above baseline, removing debris and spent powder. During annual inspection requirements, you’ll examine grids for tears, cracks, and structural damage that compromise filtration. The impact of corrosion on bent or corroded frames diminishes D.E. coating distribution and system efficiency. Replace grids showing irreparable damage, persistent cloudiness post-cleaning, or pressure inconsistencies. Most grids last 5 10 years with proper maintenance, though heavy use accelerates deterioration. When handling D.E. powder during maintenance, always wear an N95 mask to prevent inhalation of the silica-based particles. The multiport valve settings control the backwash process and enable efficient debris removal during regular maintenance cycles. Always match replacement grids to your filter model specifications. After cleaning, recharge with D.E. powder, approximately 1 lb per 10 square feet, and run your pump 30 60 minutes for even distribution.

Filter Housing and Tank Design: Creating a Sealed Enclosure

Since pool filtration depends entirely on maintaining pressure integrity, you’ll find that filter housing design focuses on creating a robust, hermetically sealed enclosure capable of withstanding sustained operational pressures. You’ll benefit from fiberglass-reinforced polymer and isophthalic polyester resin composition that guarantees corrosion resistance across decades of use. Multi-layer construction with chopped glass and woven roving reinforces structural durability while pressure testing up to 600 kPa validates safety margins. You’ll notice two-part tank designs secured with heavy-duty clamps and tamperproof bands, complemented by O-rings, gaskets, and domed end caps at critical junctions. Air relief valves and pressure gauges monitor internal conditions continuously. Access manholes with integrated O-rings maintain seal integrity during maintenance, enabling you to inspect and service internals without compromising operational security.

Clamps and Structural Components: Maintaining Pressure and Integrity

While the filter housing itself provides the foundational sealed enclosure, you’ll find that clamps and structural components work as the active restraining system that holds this pressure vessel together under operational stress. You’ll typically encounter stainless steel clamps employing single-band or multi-bolt designs that distribute pressure evenly around the tank circumference. Proper torque application is critical; industry standards mandate specific fastener values to maintain sealing performance and prevent leaks. The impact of water chemistry demands corrosion-resistant materials, particularly in chlorinated environments where oxidation threatens structural integrity. Filtration load balancing depends on correct clamp tension; uneven pressure creates stress concentrations that compromise gasket seals. You must perform regular inspections to detect fatigue or preload loss in fasteners, ensuring your filter system maintains both pressure integrity and operational safety throughout its service life.

Drain Plugs and Water Management: Easy Debris Removal

To maintain your pool system’s operational efficiency, you’ll need to understand how drain plugs function as critical access points for water removal and debris management across filters, pumps, heaters, and skimmers. You’ll find drain plugs at filter bases, allowing sediment and waste flushing after backwashing cycles. Hydrostatic plugs in main drains release excess groundwater beneath pool structures, reducing floating risks.

During seasonal considerations and pool readiness phases, you’ll rely on expansion plugs to expedite debris discharge from filter tanks and pump volutes. Pressure testing with these plugs can create water hammer effects, dislodging stuck debris in skimmer or return lines. By facilitating rapid water evacuation, you’ll prevent residue accumulation that strains pumps and compromises filtration performance. Proper drain plug maintenance guarantees your system operates reliably year-round.

Multiport Valves: Controlling Water Direction and Flow

A multiport valve serves as your pool system’s central command center, directing water flow through multiple pathways with a single rotary handle. You’ll find it mounted directly on your filter, featuring distinct ports for pump intake, return, and waste discharge. This component eliminates manual valve switching by consolidating multiple functions into one device.

| Mode | Function | Water Path |

|---|---|---|

| Filter | Normal operation | Through filter media |

| Backwash | Media cleaning | Reverse flow to drain |

| Waste | Direct drainage | Bypasses filter entirely |

| Recirculate | Circulation only | Returns unfiltered water |

Always turn off your pump before adjusting settings to prevent damage. Modern electronic control integration streamlines operation and simplifies troubleshooting common issues. Proper valve maintenance extends equipment lifespan considerably.

Backwashing and Bypass Functions: Cleaning and Maintenance Modes

Your multiport valve’s backwashing and bypass functions represent essential maintenance modes that keep your filter operating efficiently and your pool water clean. Understanding when and how to use these modes guarantees optimal system performance.

- Backwashing reverses water flow through filter media when pressure rises 8 10 psi above normal, removing trapped debris and contaminants.

- Rinse cycles follow backwashing, flushing residual debris and re-settling filter media before returning to normal filtration.

- Bypass mode redirects water around the filter for chemical treatment or troubleshooting without interrupting circulation.

- Proper valve positioning requires shutting off your pump before changing modes to prevent equipment damage.

Monitor periodic timing based on pool use; sand filters typically require backwashing every 2 4 weeks. Always check your pressure gauge and sight glass to determine cycle completion. Never adjust valves while your pump’s running.

Pressure Gauges: Monitoring System Performance and Safety

Three critical functions make pressure gauges indispensable to pool filter maintenance: they measure internal system pressure, establish your filter’s baseline operating parameters, and alert you when conditions deviate from normal. You’ll typically see readings on a 0 60 PSI dial that uses a sensitive diaphragm to display results via needle movement.

When you’re monitoring diagnostic metrics, remember that pressure 10 PSI above baseline signals filter cleaning is needed. High readings indicate clogged media; low readings suggest pump basket obstruction or pump issues. Fluctuating pressures point to air in your system.

For installation considerations, mount gauges upright on filter housing using corrosion-resistant materials. Inspect regularly for cracked faces, stuck needles, or fogging, signs requiring replacement. Maintaining ideal pressure prevents system rupture, protects seals, and guarantees efficient circulation and sanitation compliance.

O-Rings, Gaskets, and Seals: Preventing Leaks and Pressure Loss

You’ll maintain your pool filter’s reliability by inspecting O-rings, gaskets, and seals regularly for wear, tears, or hardening that compromises their sealing ability. When you apply silicone-based lubricant during installation or maintenance, you guarantee proper seat placement and prevent rubber degradation while maximizing seal effectiveness. You should replace any damaged or misshapen seals immediately to avoid leaks and protect your equipment from pressure loss and subsequent damage.

Seal Degradation and Replacement

Pool filter seals, o-rings, gaskets, and elastomeric components frequently degrade from chemical exposure, temperature swings, UV radiation, and system pressure stress, yet many operators don’t recognize failure until leaks compromise filtration efficiency or damage equipment. You’ll identify seal failure indicators through visual inspection:

- Cracking, flattening, chalking, or hardening of material

- Loss of elasticity or brittle, shrunken appearance

- Leaks at joints, filter tanks, or pump connections

- Unexplained pressure drops or difficulty maintaining system pressure

For seal material selection, match compounds to your pool chemistry. FFKM compounds withstand harsh chlorinated environments up to five years, while nitrile fails within one season. EPDM and FKM offer mid-range durability of 1 3 years under seasonal use. Replace seals promptly when degradation appears; delaying replacement escalates repair costs substantially.

Maintenance and Lubrication Practices

Consistent inspection and proper lubrication form the foundation of seal longevity and system reliability. You’ll want to inspect O-rings and gaskets every 2-4 weeks, checking for wear or debris accumulation around seals. When you reassemble filter components, apply a thin layer of pool-grade, silicone-based lubricant; petroleum products degrade elastomer materials and compromise elastomer compatibility. Avoid over-lubrication, which attracts contaminants.

You should match lubrication intervals to your cleaning schedule or perform immediately after component removal. For seasonal storage recommendations, keep spare seals in cool, dry conditions to prevent cracking or hardening. Monitor your pool’s water chemistry closely, as unbalanced conditions accelerately seal degradation. These systematic practices prevent leaks, pressure loss, and costly equipment damage while extending seal life considerably.

Frequently Asked Questions

How Often Should I Replace My Filter Pump for Optimal Pool Circulation and Energy Efficiency?

You should replace your filter pump every 8 12 years to maintain ideal pump energy efficiency and circulation. However, you’ll want to assess earlier if you’re noticing reduced water flow, higher utility bills, or frequent repairs. Your filter pump lifespan depends on usage frequency and maintenance habits. Upgrading to a variable-speed model enhances efficiency while extending operational life. Record installation dates and perform monthly inspections so you’re proactively replacing your pump before performance deteriorates.

What Are the Signs That My O-Rings or Gaskets Need Replacement Before Leaks Occur?

You’ll spot several wear indicators before leaks develop. Watch for visible flattening, cracks, or a shiny, hardened appearance, all signs of material degradation. You should notice difficulty reassembling components or your O-ring slipping from its groove. Discoloration, swelling, or a chalky residue signal chemical damage. If your filter takes longer to build pressure or you’re lubricating more frequently, act immediately. You’ve got a narrow window to replace parts before seal failure occurs.

Can I Use Different Filter Media Types Interchangeably in the Same Filter Housing?

You shouldn’t mix filter media types interchangeably without checking your manufacturer’s guidelines first. Filter media compatibility depends on your housing design; sand filters won’t accommodate DE or cellulose, while DE housings accept those three interchangeably. If you’re considering media layering strategies, you’ll need compatible grain sizes and densities to prevent channeling and clogging. Verify your filter’s specifications before switching media to maintain performance and warranty coverage.

How Do I Know When Air Bleeder Assemblies Need Maintenance or Replacement?

You’ll recognize when you need air bleed valve maintenance by noticing persistent air release, zero pressure gauge readings, or delayed water spray. You’ll require air bleed valve replacement if you discover cracks, corroded threads, or consistent air leaks persisting after cleaning attempts. Inspect regularly for debris, stiff valve operation, and water leaks around fittings. Replace components showing material fatigue early to prevent system failure and minimize downtime effectively.

What Is the Ideal Flow Rate for My Filter Pump Based on Pool Volume?

You’ll calculate your ideal flow rate by dividing your pool volume by 360 minutes (six-hour turnover standard). For filter pump sizing, you’ll need to match this GPM requirement to your plumbing diameter; 1½” PVC handles roughly 42 GPM, while 2″ PVC accommodates 80 100 GPM. You’ll verify actual performance using pressure gauges, then adjust pump RPM settings to achieve your computed target without exceeding pipe capacity limits.