Your pool filter pump converts electrical energy into mechanical force, spinning an impeller at approximately 3,500 RPM. This rotation creates centrifugal force that propels water outward while simultaneously generating a low-pressure zone that draws dirty water inward through suction lines. The pump then directs this water through your filtration system, where contaminants are trapped before clean water returns to your pool. Airtight seals maintain the vacuum pressure essential for this continuous circulation cycle. Understanding how each component works together reveals the critical maintenance steps you’ll need to keep your system operating efficiently.

The Electric Motor: Powering Your Pool’s Circulation System

Because your pool’s water must circulate continuously to maintain clarity and prevent stagnation, the electric motor serves as the system’s critical powerhouseconverting electrical energy into the mechanical force that drives your pump’s impeller at speeds up to 3,450 RPM. Your motor’s stator and rotor generate rotating magnetic fields that sustain shaft rotation, while capacitors provide essential startup torque and operational efficiency. Bearings reduce friction, and cooling fans prevent overheating during extended use. Shaft seals and gaskets protect internal components from moisture damage, directly supporting motor longevity. The TEFC design ensures your motor operates reliably in the humid pool environment. With proper maintenance including regular capacitor inspections and seasonal preparation, your motor can reliably operate for 7-10 years. When selecting your motor, consider energy efficiency considerations: variable-speed motors with ECM technology considerably reduce operational costs compared to single-speed alternatives. Your motor choice impacts both long-term maintenance expenses and your pool’s overall circulation performance.

Centrifugal Force and Vacuum Creation in Pump Operation

When you turn on your pool pump, the electric motor spins the impeller, which flings water outward through centrifugal force, transferring rotational energy into fluid velocity and pressure that propels water through your filtration system. As water accelerates away from the impeller’s center, you’re creating a low-pressure zone at the eye, where atmospheric pressure automatically pushes fresh pool water inward to replace what’s leaving. This dual action, outward force combined with inward suction, establishes the continuous circulation cycle that keeps your pool clean without requiring mechanical “pulling” of water. The friction and gravity resistance encountered in the pipes and filtration equipment means your pump must generate sufficient head and pressure to overcome these obstacles and maintain consistent water flow throughout the system. The casing surrounding the impeller directs this flowing water efficiently toward the discharge port and into your filtration system. As water enters the strainer pot, large debris is sifted out before the water reaches the filter, protecting your filtration system from premature clogging and extending its operational efficiency.

Impeller Rotation and Force

How does a pool pump transform electrical energy into the powerful circulation that keeps your water clean and clear? Your electric motor drives the impeller at approximately 3,500 RPM, converting electrical energy into mechanical force. The rotating impeller creates centrifugal force, propelling water outward from its center eye toward the diffuser. Most pool pump motors operate on alternating current, which switches directions 60 times per second to power the rotation efficiently.

| Component | Function | Output |

|---|---|---|

| Motor | Power source | RPM delivery |

| Impeller | Force generator | Centrifugal acceleration |

| Diffuser | Pressure collector | System pressure |

| Vacuum zone | Intake driver | Suction pull |

| Vanes | Flow director | Water velocity |

Impeller speed optimization directly correlates with flow rate and pressure generation. Your motor power requirements must match impeller diameter and vane design to guarantee consistent water velocity, overcome pipe friction, and maintain system pressure for effective filtration and chemical distribution throughout your pool. The impeller can become clogged with fine debris, which reduces performance and may require clearing with needle nose pliers or small wire to restore proper operation.

Vacuum and Suction Dynamics

The impeller’s rotational force doesn’t just move water outward; it simultaneously creates the low-pressure zone that pulls water into your pump system. This vacuum establishes at the pump eye, drawing water efficiently from your pool through connected suction lines.

However, suction line clogging, whether from debris buildup in skimmer baskets or blockages in intake pipes, rapidly diminishes vacuum strength and filtration efficiency. Similarly, inlet vortex interference disrupts uniform water extraction, sometimes introducing air that compromises system integrity. Even minor air leaks around pump lids and unions can weaken suction performance and prevent your system from functioning properly. Oversized pumps create excessive pressure that can damage equipment and reduce filtration effectiveness, making proper pump sizing critical for optimal system performance.

Maintaining airtight suction lines and proper water levels prevents air leaks that weaken vacuum performance. The pressure differential between your pump’s low-pressure intake and atmospheric surface pressure forces continuous water circulation, ensuring consistent debris removal and chemical distribution throughout your pool.

Understanding Airtight Seals and Their Critical Role

Because your pool pump relies on vacuum pressure to draw water through the filtration system, even minor air leaks can compromise the entire operation. Your pump’s airtight seals, including the lid O-ring, shaft seal, and housing gaskets, maintain this critical vacuum by blocking air intrusion into suction lines and the impeller.

When you neglect seal degradation factors like chemical exposure, temperature fluctuations, and normal wear, you risk losing prime and experiencing cavitation damage. Visible air bubbles in return lines signal seal failure. The pump seal itself is a 2-part seal where both halves must be replaced together to ensure a proper fit and maintain system integrity. Replacing worn seals promptly prevents cascading equipment damage and restores consistent water circulation through your filter.

Install replacement seals on clean, undamaged surfaces with light silicone-based lubrication. Prime your pump immediately after maintenance to re-establish vacuum pressure and guarantee optimal filtration performance.

The Wet End: Where Water Acceleration Begins

While your pump’s airtight seals maintain vacuum pressure, it’s actually within your pool pump’s wet end that water acceleration truly begins. This section contains the pump pot, impeller, diffuser, volute, and seals, all working together to move water effectively.

Your impeller spins at approximately 3,450 RPM, using centrifugal force to fling water outward and create flow. However, impeller wear and maintenance are essential, as debris clogging and wear ring failure reduce efficiency considerably.

The diffuser funnels water to the impeller’s center, while the volute’s spiral chamber converts velocity into usable pressure. Maintaining diffuser and volute alignment is critical; misalignment causes pressure drops, reduced flow rates, and pump noise.

Understanding these components helps you recognize when your wet end needs attention for ideal filtration performance.

How Pump Baskets Pre-Filter Debris Before Main Filtration

Before water reaches your main filter media, it must first pass through your pump basket, a critical pre-filtration stage that traps large debris like leaves, twigs, and hair before they can damage sensitive pump components or clog your filtration system.

Your pump basket functions through three essential mechanisms:

- Mesh size optimization balances particle capture with water flow, preventing debris accumulation while maintaining adequate suction.

- Basket cleaning frequency depends on debris visibility and manufacturer recommendations; regular emptying prevents cavitation risk and pump strain.

- Seal integrity relies on proper O-ring lubrication and lid positioning, ensuring airtightness that preserves prime and suction stability.

Filter Media Types and Their Filtration Performance

You’ll find that sand filter media forms the foundation of most residential pool systems, offering affordability and widespread availability despite its 20-micron filtration rating and 4 7 year lifespan. When you compare sand to glass media, you’re weighing cost-effectiveness against superior performance: glass filters particles down to 3 5 microns, lasts 10+ years, and requires less frequent backwashing. Your choice between these two depends on whether you prioritize initial investment or long-term efficiency and durability. Glass media’s negatively charged particles actively attract contaminants more effectively than traditional sand, enhancing overall filtration performance. Smaller particles captured by filters result in improved water clarity, directly improving your pool’s overall water quality.

Sand Filter Media Basics

Several filter media options exist for pool sand filters, each offering distinct filtration capabilities and performance characteristics. You’ll find that media composition directly impacts filtration efficiency and longevity. Understanding your options helps you select the right media for your pool’s needs.

- Silica sand filters particles down to 20 microns and remains the most affordable choice, though you’ll need replacement every 3 5 years.

- Zeolite sand traps particles as small as 2 5 microns and reduces ammonia, extending media replacement cycles to 4 6 years while requiring less backwashing.

- Glass media achieves 3 5 micron filtration and lasts up to 10 years, offering superior durability despite higher initial costs.

You’ll balance cost, performance, and maintenance frequency when selecting appropriate media replacement cycles for ideal pool water clarity. All filter sand undergoes meticulous processing to ensure uniform grain size and high purity levels that maximize filtration effectiveness and water quality. Additionally, the particle size should match your filter’s specifications to prevent equipment damage and ensure optimal performance.

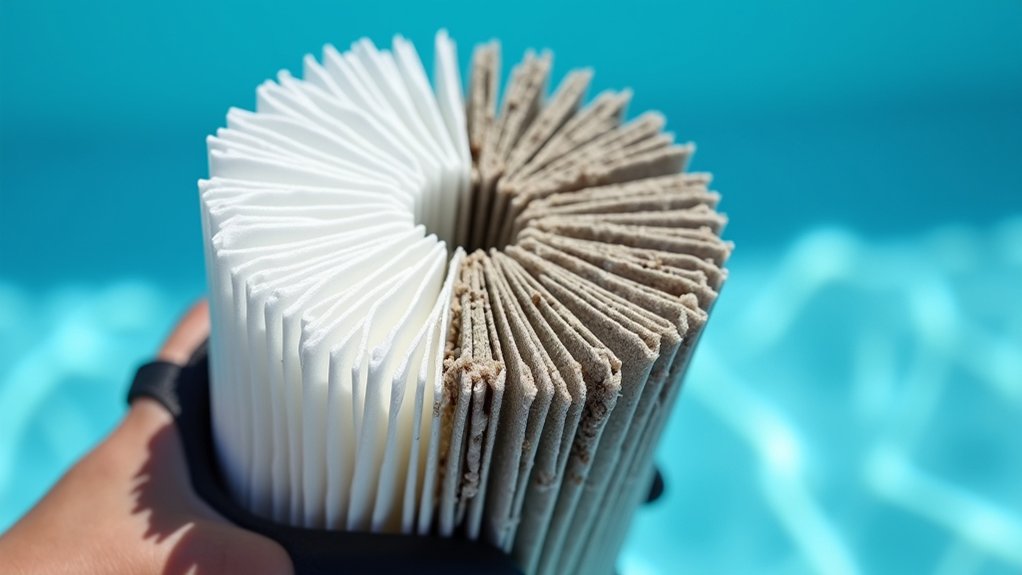

Cartridge vs. Glass Comparison

When it comes to choosing between cartridge and glass media filters, you’re weighing two fundamentally different filtration approaches that each excel in distinct scenarios.

| Feature | Cartridge | Glass Media |

|---|---|---|

| Filtration | 10 20 microns | 5 10 microns |

| Maintenance | Manual cleaning every 2 3 weeks | Backwashing every 4 5 weeks |

| Cost effective lifespan | ~2 years per element | 10 15 years |

Cartridge filters demand frequent manual removal and washing, making them labor-intensive for high-use pools. Glass media’s backwashing process saves water and time while delivering superior particle trapping. Regarding environmental impact comparison, glass media typically contains recycled content and rarely requires replacement, whereas cartridge elements become solid waste periodically. Long-term ownership favoring glass media proves more economical after six years, combined with reduced maintenance labor and chlorine demands.

Water Flow Paths: From Skimmer to Return Jets

Because water circulation determines filtration effectiveness, understanding the journey from skimmer intake through return jets is essential to pool maintenance. Your pool’s circulation system follows a precise pathway:

- Skimmer debris capture initiates the process as surface water enters the intake, trapping leaves and oils before they reach your pump and filter.

- The pump creates suction, forcing water through your filtration system where particles and contaminants are removed.

- Filtered water flows to return jets, where return jet adjustment directs clean water back into the pool.

You’ll want to orient jets to create a mild surface circulation pattern that encourages floating debris toward the skimmer. Unified jet orientation, whether clockwise or counterclockwise, ensures consistent poolwide water movement. Avoid aiming jets directly at the skimmer; instead, position them to establish balanced circulation that continuously moves the dirtiest surface layer toward skimmer intake.

Chemical Distribution Through Continuous Circulation

Your pool’s circulation system doesn’t stop at removing debris and particles; it’s also your primary mechanism for distributing chemicals evenly throughout the water. As your pump cycles thousands of liters daily, it carries sanitizers and pH adjusters to every corner, preventing stagnant zones where algae and bacteria thrive.

Chemical feeding systems work in tandem with circulation. Feed pumps deliver precise dosages directly into the return line, ensuring dosing accuracy and uniform mixing. This partnership eliminates chemical dead spots and hotspots that compromise water clarity and safety.

Consistent circulation stabilizes your water chemistry by preventing stratification and fluctuations. When your pump runs reliably, automated monitoring systems respond more effectively, reducing shock treatment needs and lowering overall chemical costs while maintaining a sanitized environment.

Maintaining Optimal Pressure and Filter Efficiency

Pressure, the silent indicator of filter health, serves as your system’s essential sign, revealing whether circulation flows freely or faces resistance. You’ll maintain ideal filter efficiency by monitoring pressure gauge readings weekly and establishing a clean baseline for your specific system.

- Identify pressure anomalies: readings 8 10 psi above baseline signal cleaning needs; persistent readings exceeding 20 30 psi indicate clogging or replacement requirements.

- Inspect systematically: examine pump baskets, skimmer components, and suction lines for obstructions that restrict flow and lower pressure abnormally.

- Execute routine maintenance: clean filters monthly, run your pump 8 12 hours daily, and use air relief valves after servicing to stabilize pressure.

You’ll preserve circulation efficiency and extend equipment lifespan through consistent pressure monitoring and preventive maintenance protocols.

System Integration: Pump, Filter, and Pool Health

While pressure monitoring reveals filter condition, understanding how your pump and filter work together in a coordinated system determines whether your pool stays clean and safe. Your pump creates outlet flow balance by drawing water from skimmers and drains, then pushing it through your filter. This pump/filter synchronization removes debris and microbes before returning sanitized water to your pool via return jets.

Proper system integration prevents stagnant zones where algae thrives. Your continuous circulation distributes chemicals evenly, reducing your sanitizer demand and costs. The strainer basket protects your impeller by capturing large debris before filtration occurs.

Operating your system 8 12 hours daily maintains water clarity and inhibits pathogen growth. Regular maintenance of seals, gaskets, and filter pressure guarantees optimal flow rates and longevity. This coordinated operation keeps your pool water safe and swimmable.

Frequently Asked Questions

How Often Should I Replace My Pump Basket and What Signs Indicate Replacement Is Needed?

You should replace your pump basket based on condition rather than following a strict pump maintenance schedule. Inspect it weekly for cracks, warping, or plastic shedding. You’ll need filter basket replacement when you notice debris bypassing the basket or difficulty reinstalling it. Don’t wait for a calendar date; replace damaged baskets immediately to prevent pump impeller clogs, reduced water flow, and costly repairs that compromise your pool’s filtration effectiveness.

Can a Malfunctioning Pump Seal Cause Water Leaks Outside the Pump Housing?

Yes, a malfunctioning pump seal absolutely causes water leaks outside your pump housing. When you’re experiencing pump seal failure, water escapes at the motor-pump connection point, creating visible puddles beneath your equipment. You’ll notice dampness spreading across your motor housing and surrounding floor area. For effective filter system maintenance, you should inspect these connections regularly. Prompt action prevents water damage escalation and protects your equipment from rust and electrical hazards that threaten your pool’s overall system integrity.

What Is the Ideal Flow Rate for My Specific Pool Size and Filter Type?

You’ll calculate your ideal flow rate by dividing your pool’s volume by your desired turnover time. Your pump sizing requirements depend on your filter type’s specifications, sand filters perform ideally at 19 25 GPM per square foot, while cartridge filters handle higher rates. Check your filter’s maximum GPM rating on the label. Following filter maintenance recommendations guarantees you don’t exceed design limits, preventing reduced filtration efficiency and equipment damage while preserving water clarity.

How Does a Variable-Speed Pump Reduce Energy Costs Compared to Single-Speed Models?

You’ll dramatically reduce electricity consumption by switching to a variable-speed pump because you’re leveraging superior pump efficiency; these models reach 90% efficiency versus 30 70% for single-speed units. You’re cutting power usage by 50%+ through the pump affinity law: minimal speed reductions generate exponential energy drops. You’ll save $300 $1,300 annually while extending your pump’s lifespan to 12 15 years, maximizing your investment’s long-term cost benefits.

Why Is My Pool Water Still Cloudy Despite Running the Pump Daily?

Your pool stays cloudy because you’re likely running insufficient filter cleaning schedules and haven’t verified your incorrect filter media settings. You’ll need to backwash more frequently, typically every 2-4 weeks, and inspect whether your sand or cartridge media’s graded layers are properly arranged. Additionally, you should confirm your pump’s runtime matches your pool’s volume; running it daily isn’t enough without proper filtration intervals and correctly configured media to trap fine particles effectively.